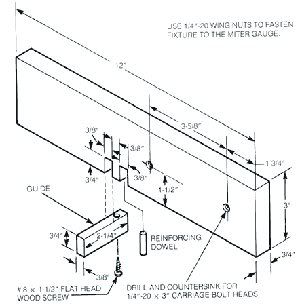

Table Saw Box Joint Jig Plans

Instructions install the stacked dado blade set.

Table saw box joint jig plans. Attach the board to the miter gauge. Cut a notch in the backer board. Making the world s simplest box joint jig. Your jig will likely have to be fine tuned after its initial setup.

I m going to use regular lumber for this example. So this collection of free woodworking jigs plans makes it easier for you to find the right jig plan you need free woodworking jig plans provided by the best woodworking related sources on the web that show you exactly how to make jigs for your woodworking shop tenon jig plans router jig plans the router box joint jig sandpaper ripping jig. Before it can be attached three holes will be drilled two mounting holes and one hole for the other hardwood dowel. One of the most useful jigs a woodworker can have for his table saw is a box joint jig.

Essential box joint jig home in on precise finger joints with this table saw sled. The 5 16 hole for the dowel is centered 1 2 from the top and 1 2 from the left side a mirror image to the one on the back fence. Attach the board to your table saw s miter gauge as shown in the picture above. The only catch is that you need a jig to help you hold and position your workpieces as you make the cuts.

Make a test joint before cutting into the material you plan on using for your enclosure. Start by setting up a stack of dado blades to whatever width you want the fingers of your joint to be. With the board. The next piece to go on the box joint jig is the plywood spacer.

By ken burton t he box or finger joint is a remarkably strong inter locking corner joint that can be quickly made on the table saw. Tablesaw box joints a shop made jig with micro adjust guarantees perfect joints. This jig allows you to quickly and strongly join boards to make stron. By tim johnson.

Box joints look best when they are cut to match the thickness of your stock. Strong great looking and quickly made box joints are an especially good choice when you have a large number of items to produce. The blade setup determines how deep the pins and sockets are on your joint.